If you’re new to sewing, the idea of creating your own outdoor gear might seem daunting, but it’s entirely achievable for everyone. This page will cover the essentials of getting started making your own outdoor gear! See the website menu above for additional educational resources that go into more detail about the points described here.

You are going to make a lot of mistakes. And it’s fine! Get your seam ripper out and try again. You learn more from making mistakes than by doing anything else.

Dont stress about hype fabrics and techniques too much. I always remember this guy I met when bikepacking around Scotland. His bike was found in a skip behind a bike shop and welded back together by a friend. Water bottle and beer bottle cap mudguards. Frame bag was a tyre stapled to a tent he found, straps sewn on with floss. MYOG is make your own gear. It doesn’t matter how you do it, as long as you make something functional that enables you to adventure.

Key Terminology

Seam and Seam Allowance: The seam is the line you sew, the seam allowance is the space between the seam and the fabric edge, which holds the stitch. Generally, I use 1⁄2 inch (1.2 cm) or 3/8 inch (1 cm)

Basting stitch: Temporary stitch, typically using a long stitch length, sewn well within the seam allowance. Used to hold something in place, such as webbing attachments or entire panels, before sewing the main seams.

An alternative is to use basting tape: a narrow (eg. 6mm) double-sided tape

Binding: Narrow strip of fabric/ribbon/elastic sewn along the edge of a project to hide the raw edges and minimise fraying. In this example image a zig zag stitch is used to sew elastic binding. A quick alternative to binding is simply running a zig zag stitch along the seam allowance to capture the raw edge of the fabric.

Pleat: A fold formed by doubling fabric back upon itself and securing it in place. It is commonly used to gather a wide piece of fabric to a narrower length. Used often for pockets where you want a wide piece of fabric for volume, but attached to a narrow panel.

Topstitch: A line of stitching on the right side of the fabric, usually used in outdoor gear for holding a seam flat, for example on a zipper. Also used for making felled seams, which are strong and easier to seam seal.

Bar Tack, Box X: Reinforcement stitches, described below

What Sewing Machine?

Basically, you can start with any sewing machine! Although most photographs in my sewing guides will show me using an industrial sewing machine, don’t be disheartened if you are using a domestic machine. MYOG Tutorials are designed to work on home machines, and even basic sewing machines can make awesome durable outdoor gear. One advantage home sewing machines have over industrials is they typically have a large array of stitch types, most crucially the zig-zag stitch for bar tacks and sewing anything stretchy.

A well maintained vintage machine can be a good option. They tend to have more metal parts and are more than strong enough for making outdoor gear. I made over 100 bags on my 1970s machine, including multiple hiking backpacks, before taking the plunge on an industrial machine (which is to be honest a bit overkill for most of these guides). Places like eBay can be a gamble for buying machines, therefore best to try in person if possible. Even if you know nothing about machines, check both the needle moves when you turn the hand wheel, and also the bobbin hook (slide out the needle plate), as broken plastic timing gears are common. I’ve had 4 vintage domestics and they’ve all had damaged timing gears that I’ve replaced. If a seller says they don’t know how to use it, there is a much higher chance it has issues.

Modern domestic machines that are generally recommended include the Janome HD3000 and the Singer Heavy Duty range. Some features to look for include:

- Heavy Duty Motor that can handle multiple layers of heavyweight fabrics.

- Adjustable Presser Foot Pressure allows you to work with a wider variety of types of fabrics easily.

- Variety of Stitches: not that important, and if anything is more things to break. Zig zag is the most useful extra stitch for MYOG projects, however other specific stitches for stretch materials can come in useful for binding pockets.

- Durability: Check reviews online and consider purchasing from reputable brands known for producing reliable equipment. Unfortunately that is harder and harder these days.

- Price: Keep your budget in mind. For many, MYOG is a way to save money on tailored custom gear. More expensive machines aren’t always what you need, as many are catered to quilters and will have computerised decorative stitches, little use for MYOG.

- Presser Foot: interchangeable feet are useful for specific use cases, such as a binding foot, zipper foot, roller or teflon foot for grippy fabrics like Hypalon.

- Walking Foot: A walking foot helps feed multiple layers of fabric through the machine evenly, reducing the risk of bunching and shifting. Rarely built into domestic machines, however you can get walking foot attachments.

Industrial Machines

If you frequently sew, particularly heavy-duty items like backpacks, you may want to explore getting an industrial machine. Contrary to popular belief, industrial machines are not necessarily more expensive than high-end domestic ones, or take up that much space; they just usually prioritise a single stitch type and durability over versatility. With home sewing machines you pay a lot more for the wide array of stitch types, of which you’ll only really use straight, zig zag, and maybe one or two others for most MYOG applications.

Four types of industrial machine to consider:

- Lightweight: Similar to household machines in operation but more powerful. Most similar to a home machine, but usually straight stitch only. Some lightweight machines can be fitted with parts that enable them to sew heavier weight materials easier (e.g. the Juki 8700). Personally, I almost wish I’d bought a cheaper lightweight machine instead of my walking foot for easier sewing of light weight materials.

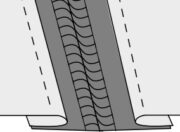

- Walking Foot: Utilising a moving foot on top and the feed dogs below to pull both the top and bottom layers, so thick seams stay aligned, but less suitable for lightweight fabrics. Excellent for backpack shoulder straps, upholstery, possibly overkill for many MYOG projects. I keep my domestic machine set-up nearby for lighter stuff and zig zags.

- Needle Feed: This type moves the needle to grab and guide fabric through the top, working with the feed dogs beneath. Often used commercially.

- Zig Zag: very uncommon, but you can sometimes find a Singer 20U which is a lightweight affordable zig zag industrial.

No Sewing Machine?

You could hand sew these guides if you have the patience, but I’d advice asking friends or family to borrow one, or if you live near a fairly large town or city there is a chance you might have a local maker or hack space. These are amazing community run projects where people share equipment and resources that it is prohibitive to own yourself. They are all unique, and some might lack a few things, but for example, my local hack space has: full size laser cutter, industrial and 2 domestic sewing machines, 3D printers, wood workshop, metal workshop including welders, vented painting room, and more. All for anyone to use at any time, for less than a netflix subscription.

If you don’t read any further down this article, make sure to check if you have a local maker/hack space, and donate money/equipment/time/anything to keep MYOG and DIY alive and accessible for everyone!

Using Your Sewing Machine

The most important thing is to first read the instruction manual! If you don’t have a manual you can find them quite easily on the internet, or one for a similar enough machine. Getting the machine threaded correctly is super important. The manual usually also includes a troubleshooting section for when things go wrong.

- Set up the basics: set up the presser foot, needle, bobbin, and upper tension assembly according to manufacturer instructions. Make sure to select an appropriate needle size depending on the chosen fabric thickness (see below).

- Practice the straight stitch and zig zag stitch, and experiment with stitch lengths and widths. To save wasting fabric, sew sheets of lined paper together and practice keeping the stitch line straight with the lines. Decorative stitches don’t typically have too much use on MYOG, but I’ve seen some rare homemade examples of bikepacking bags that have utilised decorative stitching.

- Important: Backstitch at the beginning and end of every seam by a few stitches to prevent the thread unravelling and your seam falling apart.

- Seam allowance markings on your machine’s needle plate help you keep your stitch line accurate to the required seam allowance in your pattern.

- Maintain your machine as outlined in the manual. This usually means an occasional oil (with sewing machine oil), and cleaning lint out.

- Thread Tension: Your top and lower bobbin threads should meet in the middle of the fabric to form a well-balanced stitch, see the figure below. This creates a stronger seam that is less likely to break, and any breakage is less likely to propagate the entire seam. Altering the tension is usually done by turning the tension dial above the needle on your machine. Bobbin tension is usually set-and-forget, unless making large changes to your set-up such as big thread size changes. See this article for more information

Setting Up Your Workspace

Don’t worry if you don’t have much space. I started in a cramped bedroom in a shared house at university, and even now I still have to cut fabric on the floor. But if you can, dedicate a spacious table or desk area where you can spread out patterns, fabrics, and supplies without feeling cramped.

Organise your materials and tools within reachable distance using storage solutions like shelves, drawers, boxes, or wall organisers. When you buy something, add a little label with the materials stating where you purchased it from. Quality varies a lot between suppliers, and this makes it easy to compare and know which supplier to return to!

Good lighting that minimises shadows helps you easier see markings on your fabric, assess stitch quality etc. I use a simple LED desk lamp, but you can also get lamps that attach direct to your sewing machine.

Tools of the Trade

There are so many more tools I can recommend, but in the interest of keeping this page shorter, these are the key ones I recommend.

Seam Ripper. Essential. You are going to make mistakes, and undoing these will make you appreciate just how strong your sewing is! Look close and sometimes you’ll find professionally made gear with evidence of seam ripping, misaligned seams, bobbins running out etc. Seam rippers cost almost nothing and can be found almost anywhere you can buy a needle and thread. Chunky handled ones are ideal for pushing through thick bartacked seams.

Thread Snips. Essential. Clean, easy, and precise removal of loose thread ends. Don’t torture yourself snipping thread ends with scissors.

Lighter, Candle, Hot Knives For melting thread ends, raw cut webbing ends, edges of uncoated fabrics etc. Use in a well ventilated space. Hydroponics extractor fans and some ducting are a cheap way to create an extraction system if regularly melting materials indoors.

Patchwork Quilting Ruler. Highly recommended for cutting square and rectangular pieces, the most common shapes. Some will have common angles marked on also. They are transparent so you can see the fabric underneath for accurate lining up, and is a whole world apart from struggling with set squares, edges of books etc. I use a 24 by 6.5 inch ruler, but often wish I had a 15 by 15 square also.

Cutting Mats. Get the largest cutting mat you can store and afford. Mine is A0 and I often wish it was bigger.

Rotary cutters allow for rapid precise cutting of long straight seams along a ruler edge, and cutting around curves. A 45mm blade is a good size, but go smaller if you are cutting lots of tight curves.

Fabric Scissors. Once you’ve used a rotary cutter you’ll rarely use scissors again. Don’t use your nice scissors for anything else but fabric.

Wonder Clips or Pins. Essential for holding seams together aligned, and being a third, fourth, fifth set of hands. I prefer clips to pins. Many people will passionately take opposing sides on this! For waterproof fabrics, you generally want to avoid extra pin holes. Sewing itself adds hundreds to thousands of holes anyway though, so choose your favourite.

Basting tape. A narrow (I use 6mm width) double sided tape, used as alternative or supplement to pins/clips. . Use within your seam allowance or for tacking things to face panels. Especially useful for keeping zippers looking straight and even. Try to avoid sewing through as it can gum up your needle.

Prickly Gorse Webbing Ladder Templates: A set of paper templates for perfectly aligning webbing ladders, MOLLE etc. Make holes in the paper and use a chalk pen to mark your webbing positions. They can be found as Free/Donate What You Want downloads at https://payhip.com/b/SdWuN

Scrap fabric. Essential for dialling in your thread tension, and prototyping new designs. Many fabric retailers will occasionally sell bags of fabric offcuts for cheap, or use your own leftovers, old bed sheets etc.

Presser Foot: most machines allow interchangeable feet, that are useful for specific use cases, such as a binding foot, zipper foot, roller or teflon foot for grippy fabrics like Hypalon.

Selecting Fabric and Materials

This is a quick summary of the contents of the Fabrics 101 guide.

Before starting any project, it’s important to choose appropriate materials suited for their intended use. For outdoor gear, consider factors such as durability, water resistance, and weight when picking fabrics, threads, zippers, buckles, and other components. Some brief notes about common fabrics:

- Nylon: Commonly used in backpacks, tents, and clothing due to it’s excellent tear strength, abrasion resistance and low weight compared to natural fibre fabrics. It comes in various weights and finishes, including silicone-, urethane-, and pvc-coated options for increased waterproofing. Comes in a huge variety of weights for different use cases.

- Polyester: Similar to nylon but more resistant to UV damage, but slightly lower tear strength and abrasion resistance. Like nylon, it has different coatings available for added weather protection.

- Ripstop is a type of weave with a reinforced grid pattern to prevent tears propagating, commonly found on lighter weight fabrics to increase performance. Typically not found or needed on fabrics heavier than 6oz/200gsm/420D.

- Cotton Canvas: Heavier than synthetic alternatives for the same performance, cotton is rarely found on modern outdoor gear. Some heritage brands such as Carradice still use it for bike bags.

- Thread: Choose heavy-duty polyester thread over cotton since it won’t rot when exposed to moisture or mildew.

- Zippers: Different sizes, bigger are typically stronger. #5 (5mm teeth width) is the standard you see on most gear. Waterproof zips have a coating on one side to minimise water ingress.

- Webbing: Choose nylon or polyester webbing where possible, as it is stronger than polypropylene and generally frays less. Polypropylene floats however, so it has uses for applications where you might want a floating strap, and it comes in a very wide range of colours. Seeing if your webbing floats is also a quick way to see if a seller was lying about it being nylon webbing.

Needle and Thread

Discussed in more detail on the Needle, Thread and Tension Page.

But to summarise, with some example threads made by Gutterman:

| Thread name | Tex (thickness) | Needle Size | Uses |

|---|---|---|---|

| Continuous Filament (recommended) | |||

| Tera 80 | 35 | 70/10 to 90/14 | Tarps, ultralight fabrics |

| Tera 60 | 50 | 90/14 to 100/16 | My favourite all rounder |

| Tera 40 | 75 | 90/14 to 110/18 | Backpacks, heavy fabrics |

| Tera 30 | 100 | 110/18 or 120/20 | Heavy canvas, upholstery, sails |

| Core Spun | |||

| Mara 100 (sew all) | 30 | 70/10 to 90/14 | Tarps, ultralight fabrics |

| Mara 70 | 50 | 90/14 to 100/16 | |

| Mara 50 | 60 | 90/14 to 110/18 | Backpacks, heavy fabrics |

Basic Sewing Techniques

Once you have your sewing machine and fabric ready, it’s time to start sewing! Here are a few key tips:

- Nearly all projects are sewn inside out, and then inverted to reveal the final bag. Don’t stress if the inside gets messy, it will look great on the outside!

- Start projects with a new needle. They get blunt, and are consumables! If your stitches are uneven, skipping, or generally just don’t look very neat, your first step should be to try a fresh needle. You don’t need a new needle for every project, but every 10 hours of sewing or so is a good rough benchmark. Additionally, replace your rotary cutter and knife blades occasionally

- Start and end each seam with a backstitch to stop the thread unravelling.

- Start each seam holding the loose thread ends to stop them getting sucked in while backstitching and making a big knotted mess.

- Wind a load of bobbins before starting your project. Nothing more frustrating than having to stop midway to wind a new bobbin! Some machines can wind and sew simultaneously to save time, or with some creativity can be made to.

- Practice sewing straight seams by following a marked line on a piece of scrap fabric even lined paper.

- To turn a corner, stop sewing with the needle in the down position, lift the presser foot, pivot the fabric, lower the presser foot, and continue sewing.

- Raw edges can fray and unravel over time, so it’s important to finish them properly. There are many ways to do this: encase in a binding tape, fold the seam allowance back on itself and sew flat, go over it with a zig zag stitch, roll a couple of times and sew (rolled hem).

- Topstitching involves stitching through the seam allowance on the outside, visible side of your fabric. This technique adds strength to your seams

- Reinforcement stitches such as the bar tack and box X are useful for adding webbing to your projects, shoulder straps, handles, anything that adds a concentrated stress point to your project. See this article for more information.

Beginner to Commercial Quality

Starting with smaller projects enables you to gain experience and confidence gradually. Plus, it allows you to test different fabrics, stitches, and techniques without committing too much time or resources.

On the flip side, sometimes its fun just going hard at the start and jumping straight into the big projects. All Prickly Gorse/ MYOG Tutorials sewing guides are written with complete beginners as the priority, so hopefully you should be able to pick up any guide and go from your first stitches to a commercial quality bag!

Some suggested projects in difficulty order:

- Straps with buckles: The very first thing I ever sewed was a new set of cinch buckle straps for my bikepacking gear. Simply attach a buckle to a length of webbing using a bar tack or box X stitch.

- Dog leashes: Good way to use up webbing and excess buckles.

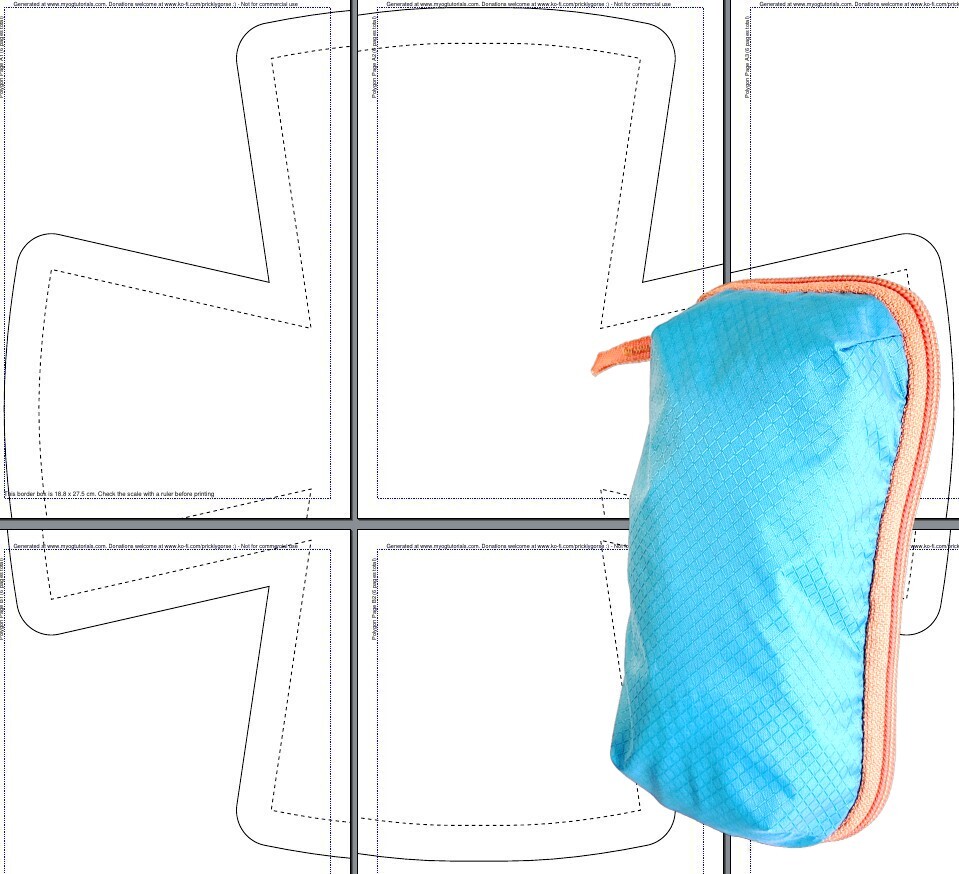

- Boxed Zip Pouches: Ideal first project to try out zips. Useful for storage bags and backpack organisation.

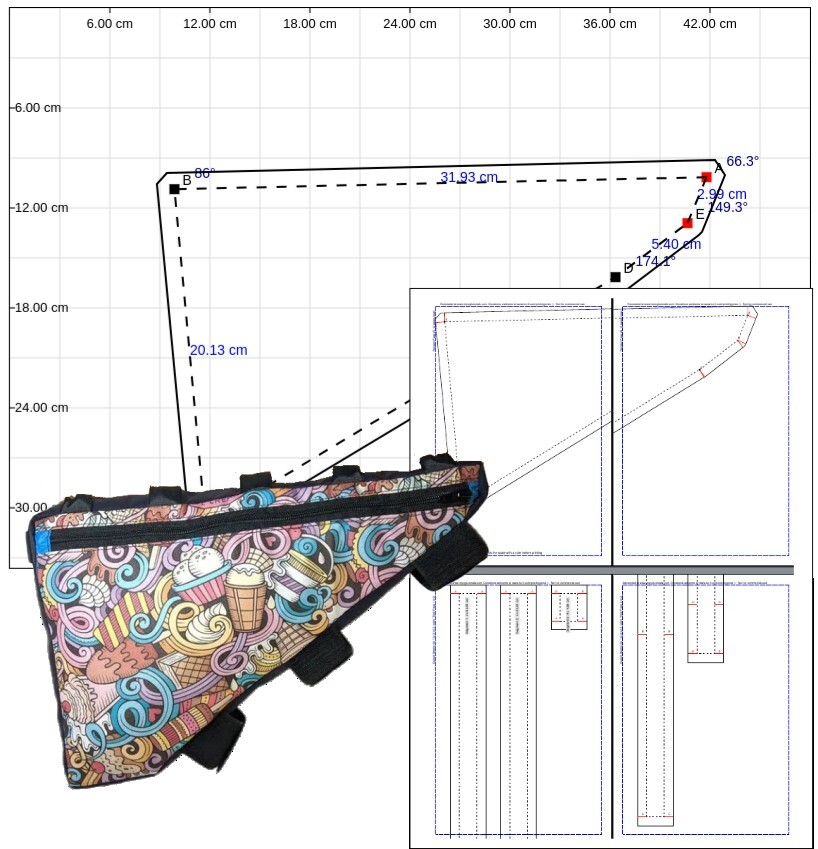

- Fanny Pack: Common first project for many people, with a twist – a darted front panel for extra volume and learning a new skill. Unique design to myogtutorials.com

- Your first backpack: The 25L day pack is a great introduction, and will be your companion for all sorts of adventures, commutes and days out.

- See the full list of MYOG Tutorials sewing guides, aimed at being the best way to start your sewing journey, from first stitch to commercial quality outdoor gear.

Go Make Some Awesome Gear!

There isn’t really a more satisfying way to experience the outdoors than using something you have made yourself.

Prickly Gorse’s MYOG Tutorials are committed to helping you get started on making your own gear. Grab your sewing machine, some fabric, one of our patterns and get started on your next adventure today!