It is easy to get lost in the details, so instead of repeating an excessively detailed already existing article, this is a quick guide to just get you going.

Check out the MYOG Suppliers page for recommended places to order high quality needles and thread for making your own gear

I do nearly all my sewing with size 14/90 to 110/18 universal needles, and continuous filament nylon or polyester thread, sizes Tex 50 to 75. Lets unpack this!

Needles

Needles come a variety of point types, and in two numbering systems for the thicknesses.

| European | American |

|---|---|

| Narrower Needles | For lightweight fabrics/thin fabric stacks |

| 60 | 8 |

| 70 | 10 |

| 80 | 12 |

| 90 | 14 |

| 100 | 16 |

| 110 | 18 |

| Thicker needles | For heavier weight fabrics/thick fabric stacks |

Size 80/12 is good for ultralight fabrics, lightweight clothing, tarp fabric etc. 90/14 is a good size for lightweight technical bag fabrics such as XPAC, 210D gridstop. 100/16 for heavier fabrics such as Cordura.

100/16 is typically the limit for most home domestic sewing machines.

For best stitch quality you should match needle size to the fabric, but I’ll be honest, I tend to just leave a 100/16 in my machine for everything from ripstop to Cordura, as 90% of my sewing is with heavier fabrics.

There are a huge variety of needle points types. Typically a good quality universal, denim or microtex (sharp) needle will be all you need for most MYOG projects, and dont stress it too much. If you are having stitch issues when using stretchy fabrics, consider trying a ball point needle.

My last point on needles is that they are consumables. Replace every 10-ish hours, or for example when starting a new large project such as a backpack. If your stitch quality is poor (skipping stitches, stitches looking offset instead of straight, rough holes, a ‘punchy’ sound when sewing), your first trouble shooting step should be a new needle.

Thread

Avoid cotton thread for most MYOG projects, unless wanting to complete a traditional aesthetic, such as Carradice bike saddle bags.

There are a lot of different ways to measure thread thickness. I personally look for the Tex number, which increases with thread thickness/strength. You want to match your thread size to your needle size, and therefore also your fabric weight. Too thick a thread in a ultralight fabric can cause puckering, and aesthetically a thread that looks out of place.

Most home machines can’t handle anything thicker than roughly Tex 70

Corespun thread has a soft, fuzzier appearance similar to cotton. Continuous filament thread has straight fibres, and is typically stronger, more abrasion resistant and sometimes easier to sew with than corespun.

Bonded thread has a thin coating that helps prevent fraying, and allows for sewing at far higher speeds in industrial settings. A nice demonstration of the difference in thread fraying between bonded and unbonded thread can be seen in this video.

Matching the thread colour to the fabric colour is helpful to hide untidy stitching when starting out 🙂

Here are a few examples of Gutterman thread.

| Thread name | Tex | Needle Size | Uses |

|---|---|---|---|

| Continuous Filament | |||

| Tera 80 | 35 | 70/10 to 90/14 | Tarps, ultralight fabrics |

| Tera 60 | 50 | 90/14 to 100/16 | My favourite all rounder |

| Tera 40 | 75 | 90/16 to 110/18 | Backpacks, bike bags, heavy fabrics |

| Tera 30 | 100 | 110/18 or 120/20 | Heavy canvas, upholstery, sails |

| Core Spun | |||

| Mara 100 (sew all) | 30 | 70/10 to 90/14 | Tarps, ultralight fabrics |

| Mara 70 | 40 | 90/14 to 100/16 | |

| Mara 50 | 60 | 90/16 to 110/18 | Backpacks, heavy fabrics |

Sometimes a thread has a generic name

| Thread name | Tex | Needle Size | Uses |

|---|---|---|---|

| V46, #46 | 45 | 90/14 to 100/16 | Tarps, ultralight fabrics, all rounder |

| V69, #69 | 70 | 110/16 to 120/18 | Backpacks, heavy fabrics |

| V92, #92 | 90 | 130/20 | Heavy canvas, upholstery, sails |

Thread Spools and Stands

Thread is wound onto spools in two ways.

Stacked is simply wound in neat rows/lines, and these spools should be placed on the pin on the top of your machine.

Cross-wound spools and cones have thread that is wound in a criss-cross way, and visually the thread overlaps diagonally. These are designed to be pulled from the top. Ideally you use a purchased cone holder and thread stand, but I simply put the cone in a cup and have duct taped a coat hanger to the side of my machine….

Thread Tension

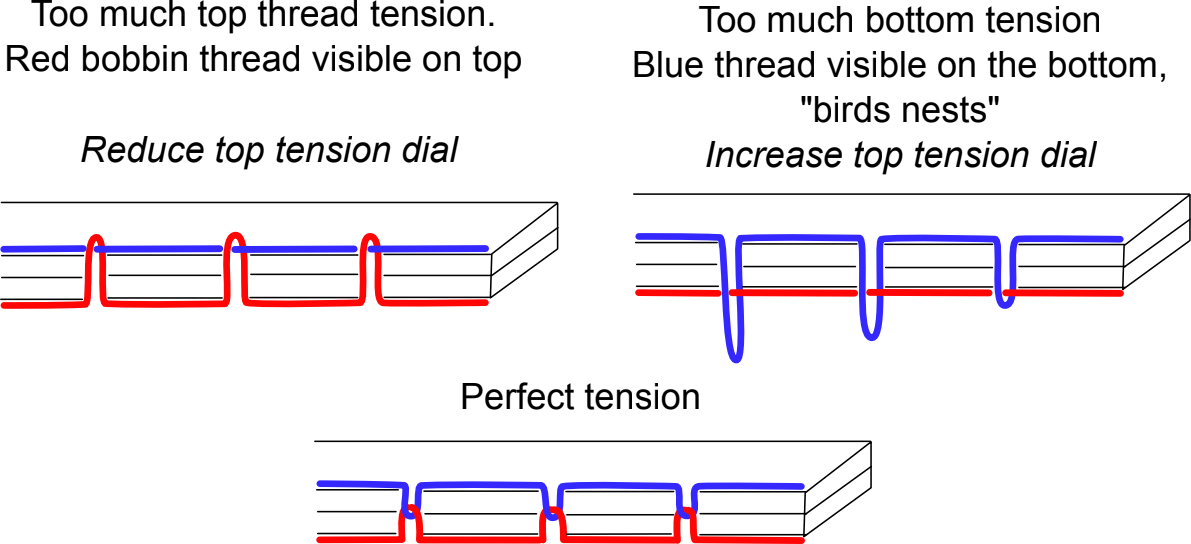

Your top and lower bobbin threads should meet in the middle of the fabric to form a well-balanced stitch, see the figure below. This creates a stronger seam that is less likely to break, and any breakage is less likely to propagate the entire seam. Altering the tension is usually done by turning the tension dial above the needle on your machine. Bobbin tension is usually set-and-forget, unless making large changes to your set-up such as big thread size changes. Consult your sewing machine manual if unsure

You will need to regularly change tension when changing the thickness of your seam as more or less layers are stacked. Fabric scraps are ideal for testing your tension settings before committing to your project. One easy way to dial in your tension is to reduce the top tension dial to zero, sew a few stitches, increase to 1, sew a few stitches etc until at 10, or your highest tension. You will be able to visually see the bobbin thread gradually get pulled up as the tension gets too high.

This article contains affiliate links to quality products from reputable MYOG companies to help support this site, at no extra cost to yourself.