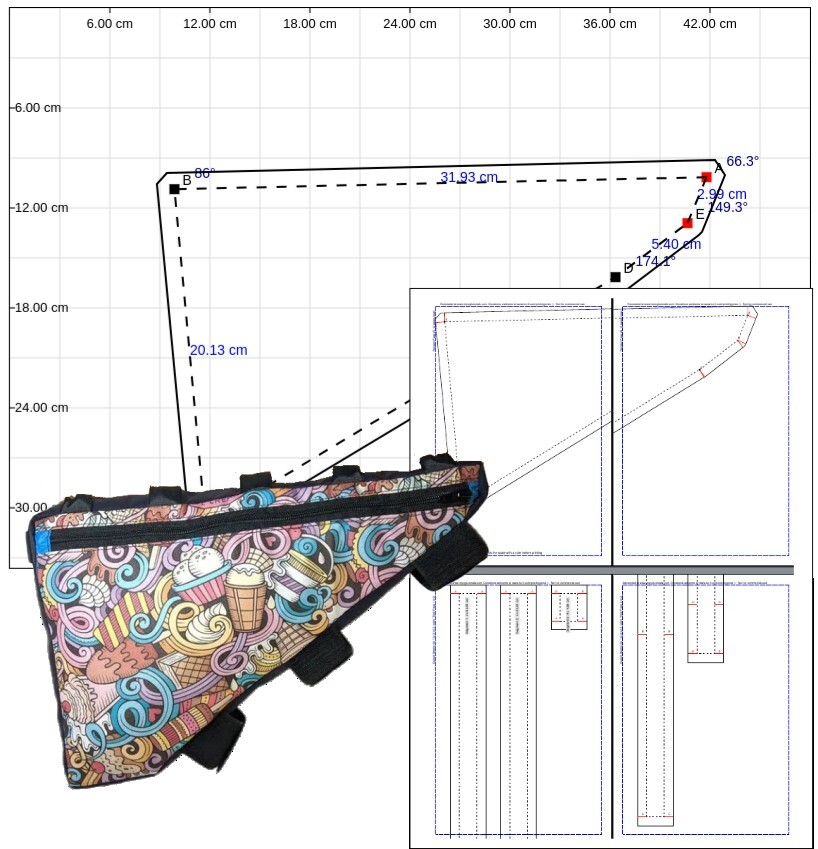

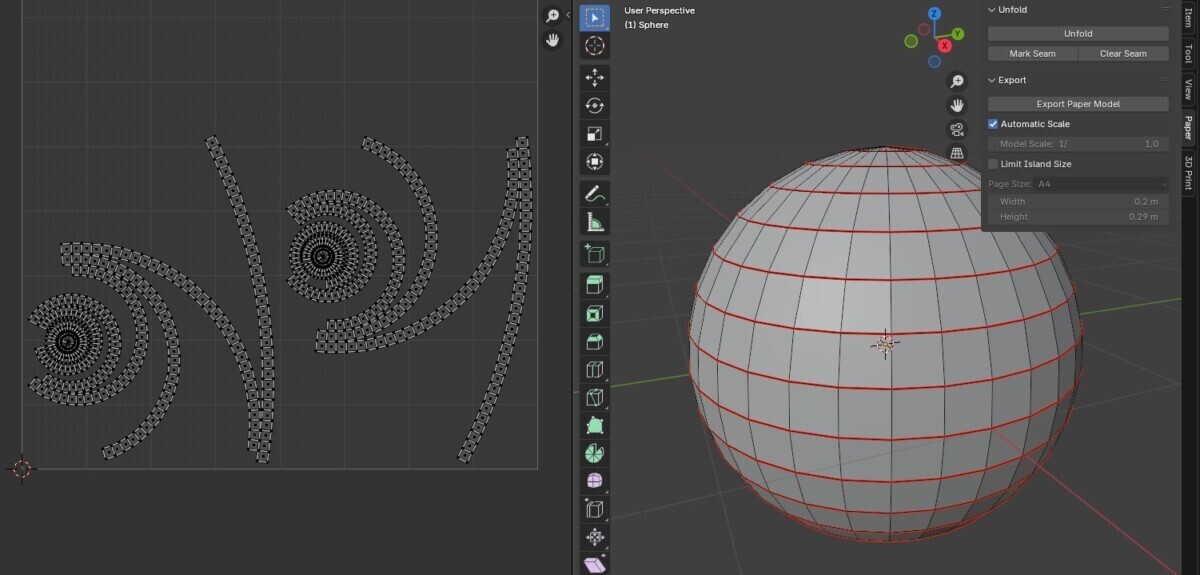

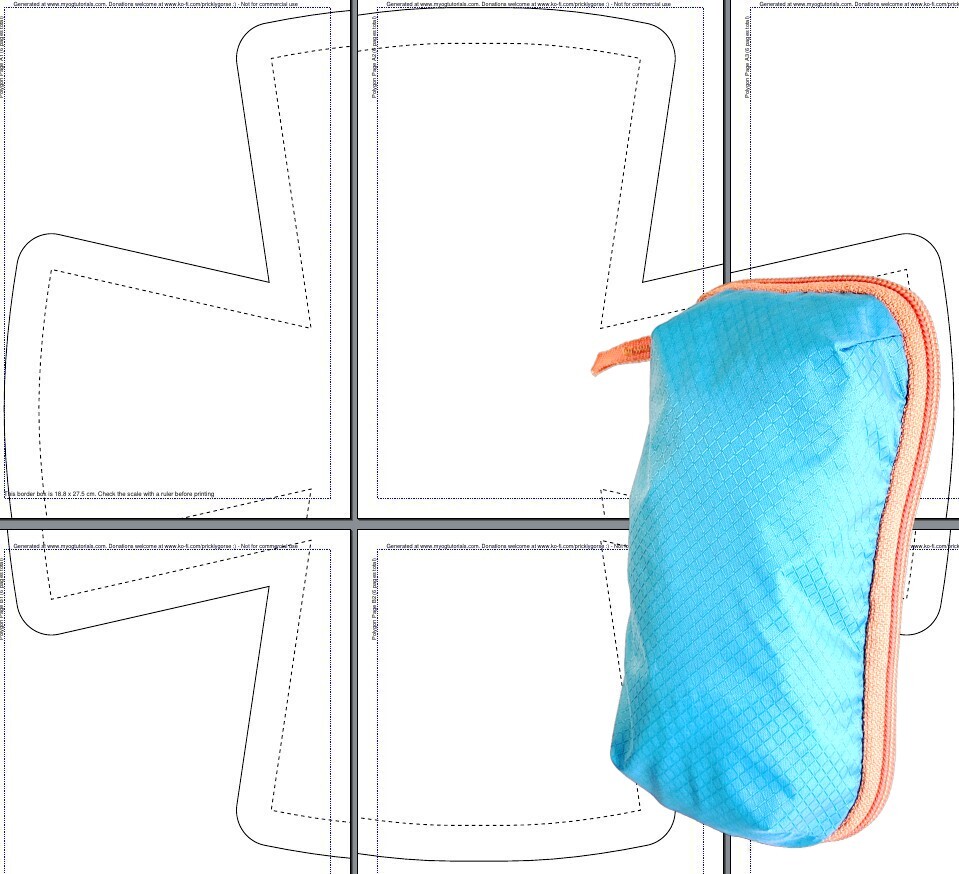

| NEW: Inkscape extension to help make your own sewing patterns. Especially handy for making your own frame bags! https://github.com/pricklygorse/Inkscape-Unroll-Flatten-Extension or Draw and Generate Patterns Online! https://myogtutorials.com/online-automatic-pattern-generator/ |

This is a rough guide to sewing your own simple custom sized zippered frame bag. It is an ideal project for your bikepacking adventures, and a super versatile bag to keep on your bike all year round. This guide is a template to build upon yourself if you want to add more features such as dividers, double decker zips etc. A polished comprehensive guide covering all common options will be available at some vague point in the future.

After making a your own custom frame bag, why not see my current bikepacking range of sewing guides here, featuring seat packs and stem feed bags.

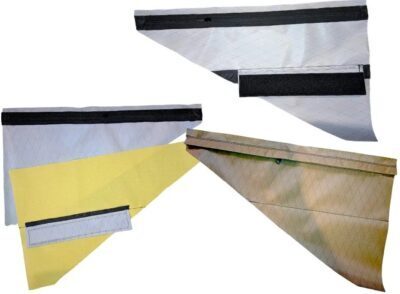

Fabrics: Any outdoors fabrics really.

XPAC VX21 is the tried and tested standard that most custom bag companies use. Ecopak is a near like or like recycled equivalent. Or 500D cordura, 210D robic ripstop, cotton canvas, old pair of jeans.

A more abrasion resistant fabric is recommended for the middle strip panel, such as 500D to 1000D cordura.

See the MYOG Suppliers page for locations of high quality fabric suppliers and the Fabrics 101 page for a bit more info on fabrics

Zips: #8 or #10 size for a full frame bag, #5 for half or small bags. See my zips article for more info

Make a template of the shape you want out of cardboard. Test to ensure it fits in your bike frame.

When making full sized full frame sized bags, a squared off bottom on full frame bags helps stop small objects ending up hard to reach in a deep tight corner.

If your frame allows for it, a squared or rounded off nose means you don’t have to sew around and push out a super tight corner.

Additionally mark any other useful reference points, like bottle cage bolts, as these will need avoiding when deciding strap placement.

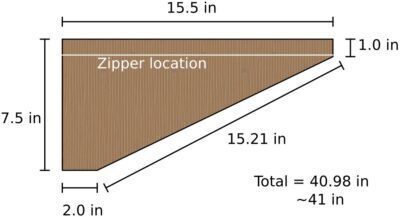

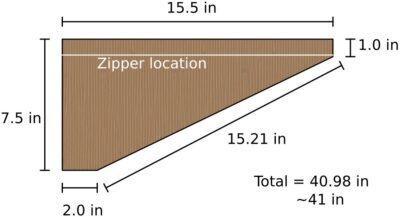

Measure all the edges of your cardboard template and write them on your template. Although I’m from the UK, I’ve got a bad habit of using inches because a lot of sewing tools such as sewing machine needle plates, cutting mats and patchwork rulers use them. Apologies to all non-US readers.

If you are using curved corners, you’ll need to work out the curve lengths also. Rolling a ruler around the edge works, as does placing some string along the curve and measuring the string.

Accurately trace this template to a new piece of card. Add seam allowances to this template, then cut out this second larger template. I like to use ½ inch for the seam allowance as this is marked on almost all sewing machine needle plates, and gives plenty of leeway for measurement mistakes and durability if your fabric frays.

Make a small pencil nib sized hole at all the seam allowance corners of your template. If your template has curved corners, make little holes at the start and end of the curved bits.

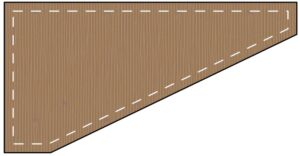

Use the second larger template to mark and cut the fabric. Flip the template upside down to mark the second side panel to form a mirrored copy. You don’t need to draw the seam allowances on the fabric, they are just shown for reference in the figure.

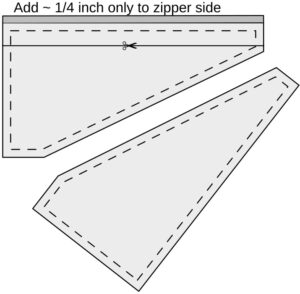

On the side you are adding a zip, add roughly 1/4 inch extra to the top of the template. This is to give some leeway later if the finished side panel doesn’t quite match the template size anymore after adding the zipper.

Fabrics like XPAC are quite difficult to orientate to minimise fabric waste if you want the diamonds facing the same way on each side.

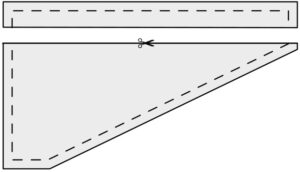

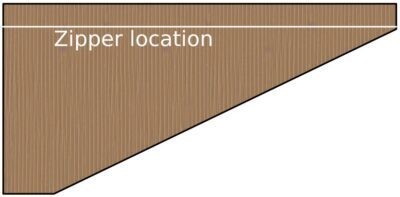

Snip the zipper side panel into two pieces at the zipper cut line.

When choosing a zipper, larger the better usually for frame bags which can get a lot of grit and mud in them. Moulded tooth zippers are the most mud resistant, and size #8 to #10 are recommended. Smaller zippers like the standard #5 might be a better option aesthetically however for smaller frame bags.

It is good practice to add an extra strip of fabric sewn on either side of the zipper that extends a bit beyond the zip. This bit of fabric will be sewn into the seam allowance of the side panels, not the zipper itself. The zipper wont bend quite as nicely as the fabric when the bag is opened the correct way around.

If buying waterproof zippers, buy from reputable retailers. Cheap ones I’ve bought from eBay before have delaminated in just a week of usage.

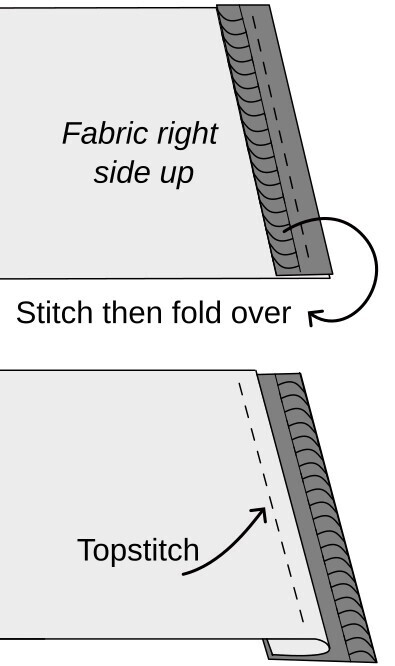

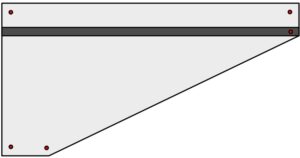

Sew half of the zipper, upside down, to each side panel half, then fold back on itself and topstitch.

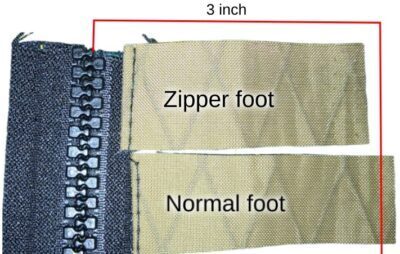

Depending on how close you sew to the zipper, your panel may have changed size. See the example photo in which I’ve used a zipper foot and a normal foot, showing the fabric length afterwards varying by 1/4 inch. This is why I recommend adding extra fabric to the side panels in the previous steps.

If you sew directly down the middle of the zipper tape, the panel will remain the same size, and not require adding extra fabric. But there is a chance you may not be super accurate when sewing, and trimming off some excess fabric is far easier than seam ripping! Adding extra and trimming is also easier than working out the seam allowance you require for different zip widths and sewing machine presser feet

Insert a zipper slider onto the two halves of zipper tape to close the bag. Make sure the zipper closes towards the nose of the bag/handlebars.

Overlay the template with seam allowance over this side panel. If the side panel is now too large, trim it down to match the template.

Using the holes you made previously in the cardboard template, use a pencil to mark a subtle small dot at each corner of the seam allowance onto the right side of the fabric. You will be using these dots later as alignment marks instead of drawing out the entire seam allowance.

Alternatively if you are worried about the dots being visible on the final bag (if you are accurate your middle piece will cover them) just make markings in the seam allowance that match where the corners will be.

Now to work on the middle strip that forms the width of your frame bag

First, decide your bag width. Anywhere from 4 to 8cm is usually fine. Any wider and you are at risk of the bag bulging out and rubbing your legs while riding. For wider bags you’ll probably want to sew in a velcro divider that will hold the bag together in the middle.

Add double your seam allowance to your chosen width (I use 1/2 inch, so add an extra inch to the width).

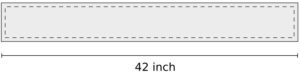

The length of your fabric strip is the sum of all the side lengths, plus double your seam allowance. This length may end up being longer than the length of your fabric, so you will need to split this into smaller lengths. Best to use strips that are the same length as a side edge, so you don’t have an out of place looking seam midway along. Remember each strip needs seam allowance adding before sewing together.

Mark each individual side panel length onto your fabric strip’s seam allowance, top and bottom. These marks will line up with the pencil dots when assembling the bag.

Now decide how you want to attach the bag to your bike.

The main ways are a webbing ladder and double sided velcro loops, sewn-in velcro at defined places, and/or little loops for threading cord through and lacing the bag to the bike. It is up to you to decide which method you prefer.

Webbing ladders allow flexibility with velcro placement but are time consuming to make. Sewn in velcro and loops are the lightest weight options.

Add your preferred attachment method to the middle strip.

If making a webbing ladder, 2 inch (50mm) webbing works well if your bag width is 6cm or more. Add regular bartack stitches about 1.5 inch (38mm) apart, depending on how well they can be spaced along the length.

If loops/velcro, basting stitch them to the middle panel. A basting stitch is a quick stitch usually within the seam allowance to hold stuff in place before sewing the main seams.

An attachment point should be made adjacent to the zip so when the zip is pulled it closes instead of pulling the bag.

Final steps are to sew the middle strip to your side panels. I recommend sewing to the non-zipper side panel first, as this is the easiest to replace if you somehow make a mistake with your middle strip lengths.

Some people prefer to sew the middle strip closed into a loop, then sew this to the side panel.

Some prefer to sew the strip on as is then sew it closed at the final step. The second method is useful if your bag has a really sharp corner. Starting and finishing sewing at this corner, then sewing closed, is easier than trying to bend the middle panel around a very sharp corner. Another advantage of this second method is you get a bit of leeway to correct any alignment mistakes at the end by using up some of the seam allowance.

Start sewing 1/2 inch inwards (your seam allowance) from the edge of the fabric.

Use the alignment marks on the middle panel and the subtle pencil marks you made on the side panels to make sure each corner lines up at the end of each edge. If you are looking like you’ll end up a little off you can push/pull the required top or bottom fabric layer a little to slightly uneven feed the fabrics. Be subtle with this or you’ll pucker your work.

If you are struggling with corners, you can make relief cuts. Don’t cut all the way to the seam line as you need some fabric left to hold the stitch.

Sew the middle strip together to close up the bag once both side panels are sewn on.

Optionally bind the raw edges of your seam allowance with grosgrain. This will help maximise your bag’s life if using fabrics prone to fraying.

Open the zipper, invert the bag, and admire your work

If this guide helped you make something awesome and you’d like to share, tag me on Instagram @pricklygorse, or post on reddit r/MYOG as I’d love to see your creations 🙂

This is the most basic bike frame bag. Some suggestions to experiment with for your next build:

- Add a liner fabric to the inside.

- Add a liner to the middle panel so you can insert a stiffener.

- Binding the internal seams for a professional finish

- Internal pockets.

- Hydration ports

- Storm flaps over the zipper

- Zipper garage so the tiny bit of zipper that remains open when zipped closed gets less water in it

- Internal dividers that can be separated

- Double decker two zip frame bag

- Roll top frame bags

A future comprehensive guide will cover all these options.

Double Decker Cheatsheet Photo

Double decker frame bag with rain flaps and a thin non-drive side ‘map’ pocket

The map pocket side is two long stitches, first stitch through the liner fabric and fold-down divider, and a second stitch line 1/4 inch above this through the liner and outer fabric, to hold the divider seam allowance flat.

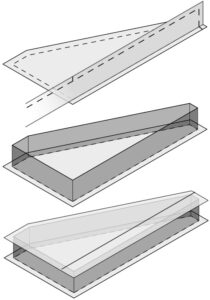

Roll Top Bags

I’ve had a few questions regarding how I make my roll top frame bags. At some vague unspecified point in the future I’ll elaborate more on these, but this image will hopefully explain my approach to them.

One side panel is taller and folds over. The top panel is wider (could be two pieces if you want a stronger gusset piece and thinner, more supple rolltop). These two pieces are designed so the roll flap is about 5 inch long. There is a gusset around the sides and bottom (not shown).

The opening is tapered inwards so the entry is narrower than the main bag, which helps with water resistance and less bulk to rub on your knees.

I have also played around with ones where the roll flap was midway along the seam, so you just follow the instructions for the zipped bag above, and insert the roll top into the top seam. However, I disliked the aesthetics and faff of that, especially with binding the raw edges.